Siemens is a global leader in industrial technology, focused on industry, infrastructure, mobility and healthcare. The company’s operations depend heavily on the smooth functioning of complex machinery, where even short periods of downtime can result in significant production losses, increased costs, and supply chain disruption.

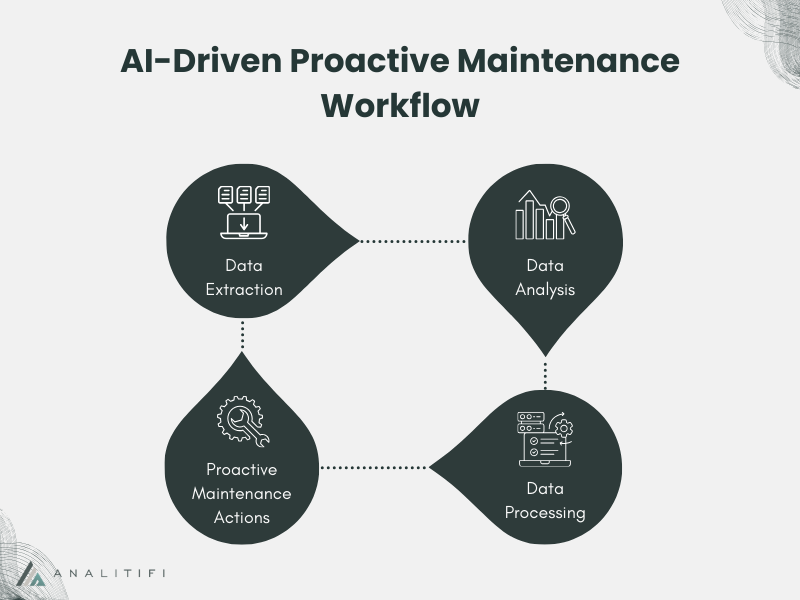

Traditional approaches to maintenance, whether reactive or preventive, often prove inadequate. Reactive strategies address problems only after they occur, while preventive maintenance based on fixed schedules may lead to unnecessary interventions or overlooked failures. To address maintenance challenges, Siemens has adopted AI-based predictive maintenance which can detect patterns, contextualize findings, and make reliable maintenance recommendations to minimize downtime and improve operational efficiency.

This case study highlights how Siemens leverages AI-driven predictive maintenance to transform its maintenance approach. Using machine learning models on real-time data, Siemens can prevent unplanned downtime and increase maintainer productivity through better planning.

The Challenge

For industries, the cost of unexpected equipment failures accounts for 42% of unplanned downtime costs. Unplanned downtime does more than halt production, it wastes resources, delays customer deliveries, and erodes customer satisfaction. Because uptime directly affects revenue, even a few hours of disruption can translate into millions of dollars in losses.

Siemens provides a comprehensive perspective on the challenges and strategies associated with predictive maintenance in large-scale operations. In their white paper titled “Why is Predictive Maintenance so hard?” Siemens discusses the complexities of implementing predictive maintenance, particularly in environments characterized by vast amounts of sensor data and the need for real-time analysis. They highlight that traditional preventive maintenance schedules are often inefficient, as servicing equipment too early can waste resources, while waiting too long increases the risk of unexpected failures.

They emphasize the importance of overcoming data silos across plants and business units to achieve unified insights, which are crucial for accurate failure prediction. Their approach involves leveraging artificial intelligence to analyze large volumes of data from various sources, enabling proactive maintenance strategies that reduce downtime and enhance operational efficiency.

Additionally, Siemens’ blog post “Manufacturing process improvements you can make by leveraging data” outlines how predictive maintenance, powered by the Industrial Internet of Things (IIoT) and AI, utilizes machine condition data to forecast potential failures. This approach allows manufacturers to intervene just in time, minimizing disruptions and extending asset life. The integration of real-time data and analytics empowers teams to move from reactive to proactive maintenance, thereby improving overall manufacturing efficiency.

These sources from Siemens underscore the critical role of AI and real-time data analysis in transforming maintenance strategies from traditional, schedule-based approaches to dynamic, condition-based systems. By addressing data fragmentation and leveraging advanced analytics, Siemens aims to optimize equipment reliability and operational performance across its global operations.

Siemens’ Predictive Maintenance Strategy

Predictive maintenance uses artificial intelligence to anticipate equipment issues before they occur. Unlike traditional reactive or preventive strategies, Siemens’ approach relies on advanced machine learning models and continuous monitoring to identify the exact point when a machine requires servicing by using Senseye Predictive Maintenance. This allows the company to reduce unnecessary maintenance while dramatically lowering the risk of unexpected breakdowns.

Siemens harnesses AI to analyze massive streams of data from IoT sensors, machine logs, and telemetry systems. Variables such as vibration, temperature, pressure, and energy consumption are continuously monitored to build a detailed view of equipment health across its global operations as mentioned in their “Data, AI, and Sustainability in Predictive Maintenance” blog. AI models trained on this data detect anomalies, forecast potential points of failure, and optimize maintenance schedules for maximum efficiency.

By adopting AI-driven predictive maintenance, Siemens has created a scalable strategy that improves reliability across complex industrial systems. The result is fewer disruptions, reduced maintenance costs, and higher operational efficiency, enabling Siemens to meet customer demands with greater consistency while maintaining a competitive edge.

AI in Action at Siemens

Siemens’ Senseye Predictive Maintenance starts by ingesting machine condition data, operations logs, and historical records directly from existing systems, such as plant historians or IoT middleware, with no additional hardware required on-site. That data is fed into a cloud AI/ML platform that automatically learns from diverse sensor inputs to detect anomalies, forecast failures, and uncover early warning signals that may go unnoticed by human monitoring.

The platform delivers insights through intuitive dashboards and also supports a Maintenance Copilot interface powered by generative AI, enabling users to query equipment health in natural language and receive contextual recommendations based on historical cases. By bringing actionable visibility into the condition and risk of assets, Senseye helps maintenance teams anticipate issues, prioritize work, and minimize unplanned downtime, transforming maintenance from reactive to proactive care.

Business Impact & Results

Implementing AI-driven predictive maintenance can have a significant impact on overall business performance. One of the most immediate benefits is the reduction of unplanned downtime, which lowers operational costs and prevents disruptions to critical processes. By identifying potential equipment issues before they escalate, companies can maintain smoother operations, avoid production bottlenecks, and mitigate the cascading effects that unexpected failures often create.

Beyond cost reduction, predictive maintenance supports longer asset lifespans and improved operational efficiency. Equipment that is continuously monitored and maintained operates more reliably and at peak performance, reducing the need for premature replacements or emergency repairs. This proactive approach also enables organizations to allocate maintenance resources more strategically, optimize workforce scheduling, and manage spare parts inventories efficiently, preventing both shortages and excess.

The benefits extend to overall operational productivity. By streamlining maintenance workflows and prioritizing tasks based on AI-driven insights, teams can focus on high-value activities rather than constantly reacting to crises. This creates a more predictable and efficient work environment, where both human and material resources are used optimally.

A 2024 survey by MaintainX found that 65% of maintenance professionals believe proactive maintenance is the most effective way to reduce unplanned downtime incidents.

The impact of AI-powered predictive maintenance is measurable. Organizations can see significant reductions in unplanned downtime, lower maintenance costs, and improved utilization of critical assets. These results show that proactive maintenance practices not only enhance short-term operational performance but also generate long-term value, enabling companies to respond more quickly to challenges, operate more efficiently, and maintain a competitive edge in complex industrial environments.

Conclusion

Siemens’ adoption of AI-powered predictive maintenance demonstrates how advanced analytics can transform industrial operations. By ensuring high-quality data, fostering collaboration across teams, and continuously refining predictive models, Siemens has reduced downtime, extended equipment life, and optimized maintenance resources.

Predictive maintenance has proven to be more than just a maintenance strategy, it is a driver of resilience, efficiency, and long-term growth. It provides a competitive advantage in today’s fast-paced industrial environment, where uptime and reliability are critical to success.

At Analitifi, we help organizations harness the power of AI and predictive analytics to drive operational excellence. If your goal is to reduce downtime, cut maintenance costs, and gain actionable insights from industrial data, we can help you transform maintenance operations and unlock the full potential of your assets.