In today’s data-driven manufacturing environment, increasing output while controlling costs and maintaining quality is a constant challenge. Many organizations face unplanned downtime, high maintenance costs, and production inefficiencies due to a lack of clear visibility into their operations.

These challenges often result from fragmented data and limited access to real-time performance metrics. Without a unified view, it becomes difficult to identify where improvements are needed or how to allocate resources effectively.

Manufacturing analytics provides a foundation for better decision-making, offering real-time operational insights that drive smarter strategies. With the right tools, manufacturers can track key metrics, uncover operational inefficiencies, and take proactive steps to reduce downtime and optimize performance.

Leading manufacturers are using data to align operations with business objectives, improve responsiveness, and strengthen profitability. Turning raw operational data into clear insights enables faster, more strategic decisions at every level of the organization.

In this article, we’ll explore:

- The transformative power of data analytics in industrial manufacturing

- Key performance metrics that drive operational excellence

- Practical strategies for leveraging data insights

The goal is to demystify data analysis and demonstrate how it can be a game-changing tool for manufacturers of all sizes. Whether you’re managing a small production line or overseeing a complex industrial ecosystem, understanding the power of data is no longer optional, it’s essential.

From predictive maintenance to performance optimization, we’ll guide you through the data-driven revolution that is reshaping industrial manufacturing.

Key Metrics That Drive Smarter Preventive Maintenance

Effective preventive maintenance relies on pinpointing the optimal time and location for intervention, rather than reacting to equipment failure. So how do you know if your maintenance efforts are paying off? Or which machines should be prioritized?

With data.

By tracking the right metrics, you can move from reactive maintenance, waiting until something breaks, to a predictive, strategic approach that saves time, money, and stress. Below are four essential metrics that tell a powerful story when it comes to optimizing your preventive maintenance efforts.

Mean Time Between Failures (MTBF)

MTBF represents the average operational time between system failures. This metric is calculated by dividing the total operating time by the number of failures over that period. At 4,459 hours, this example indicates equipment typically runs for about 186 days before experiencing a failure.

For maintenance professionals, MTBF serves as both a diagnostic and predictive tool. A decreasing MTBF signals deteriorating reliability, while improvements in this metric validate effective maintenance strategies. The real power of MTBF lies in its ability to transform maintenance from calendar-based to usage-based scheduling. For example, if historical data shows a particular machine component consistently fails around 4,000 operating hours, maintenance can be strategically scheduled at 3,500 hours, preventing unexpected downtime.

Knowing your MTBF is great. But knowing why it’s dropping on Line 2, only during night shifts, after a new part supplier was introduced, that’s where the value is.

Machine Downtime Costs

The machine downtime costs represent the financial impact of equipment failures across operations. The true cost of downtime extends far beyond the immediate repair expenses. It encompasses lost production opportunities, idle labor costs, missed delivery deadlines, potential contractual penalties, quality issues during restart, and even long-term customer dissatisfaction.

For maintenance decision-makers, quantifying downtime costs transforms maintenance from a cost center perspective to a profit protection strategy. By assigning specific dollar values to the downtime of different machines or production lines, organizations can prioritize preventive maintenance resources where they deliver the greatest financial benefit.

Tracking these costs over time also provides concrete evidence of maintenance program effectiveness. Declining downtime costs indicate successful preventive strategies, while increases may signal the need for program adjustments or equipment upgrades. This financial metric often proves vital when justifying investments in advanced monitoring technologies, predictive systems, or equipment modernization to senior management.

Machine Failure Rate

The machine failure rate metric represents the proportion of equipment experiencing failure during a specific measurement period. A 30.9% failure rate indicates nearly one-third of machines failed in some capacity, which is significantly higher than industry best practices would target.

Failure rate analysis becomes particularly valuable when segmented by machine type, manufacturer, age, location, or operating conditions. These comparisons can reveal patterns not obvious from overall numbers. For instance, higher failure rates during particular shifts might indicate training gaps, while geographic variations could point to environmental factors or maintenance practice differences.

Beyond identifying problem areas, tracking failure rate trends over time provides feedback on maintenance strategy effectiveness. Declining failure rates validate maintenance improvements, while persistently high rates despite increased maintenance suggest a need to reconsider the approach entirely. When combined with failure mode analysis, the specific ways equipment fails, this metric helps maintenance teams target the root causes of recurring problems rather than simply treating symptoms.

Maintenance Efficiency Score Per Machine

The maintenance efficiency score per machine metric evaluates maintenance effectiveness by considering multiple factors including repair time efficiency, first-time fix rate, prevention of repeat failures, and adherence to planned maintenance schedules. The 86.0% score indicates good but not optimal maintenance performance.

For maintenance managers, this score offers a balanced assessment that goes beyond simple completion of maintenance tasks to measure actual outcomes. Low efficiency scores on specific machines highlight opportunities for technician training, procedure improvement, or parts quality review. Conversely, consistently high scores can identify best practices worth standardizing across the organization.

This metric also helps balance the competing demands of maintenance thoroughness and operational uptime. By tracking efficiency alongside other metrics like MTBF, organizations can fine-tune maintenance frequency and depth to achieve optimal equipment reliability without excessive maintenance costs or unnecessary production interruptions.

The Integration of These Metrics

When these four metrics are analyzed together, they create a maintenance intelligence framework that drives continuous improvement. For example, a machine with declining MTBF, increasing failure rate, high downtime costs, but adequate maintenance efficiency might indicate end-of-life equipment requiring replacement rather than maintenance issues.

Advanced maintenance organizations often develop scoring systems that weight these metrics based on their specific operational priorities. Some might emphasize downtime costs in high-throughput environments, while others might focus more on failure rates in safety-critical applications.

The ultimate goal of tracking these interconnected metrics is to move beyond reactive maintenance toward truly predictive maintenance strategies. By understanding not just when equipment fails, but why and at what cost, organizations can develop increasingly sophisticated approaches that optimize both equipment reliability and maintenance resource allocation. This data-driven approach transforms maintenance from a necessary expense into a strategic advantage that supports production goals while minimizing total ownership costs.

Improving Your Operations

Performance metrics serve as both a snapshot of current operations and a diagnostic tool for uncovering inefficiencies.By translating data into actionable strategies, you can drive smarter decisions, reduce waste, and boost efficiency across your entire operation.

Schedule Smarter Maintenance

Instead of relying solely on fixed service intervals, data can help you implement condition-based maintenance. For example, if certain equipment shows higher failure rates during specific shifts or under particular load conditions, that’s a clear signal for targeted inspections. By using metrics like run-time hours, output rates, and deviation from normal operating parameters (e.g., vibration, temperature, or pressure), maintenance can be triggered by actual performance rather than the calendar. This ensures that servicing happens only when needed, avoiding both premature interventions and costly breakdowns.

Reduce Downtime

Downtime often follows subtle signs, like fluctuating energy use, unusual noise patterns, or rising operating temperatures. When these indicators are tracked in real time, small issues can be resolved before they spiral into major disruptions. Predictive analytics makes this possible by identifying early warning signs across your fleet. Equipment that plays a critical role in production flow can be proactively serviced during natural pauses in operations, minimizing disruptions and preventing cascading delays.

Improve Spare Parts Management

System-wide analysis of usage trends, failure histories, and procurement lead times enables smarter inventory control. If some components are consistently overstocked due to outdated maintenance practices, that ties up capital unnecessarily. By aligning parts inventory with real-time data and predictive maintenance needs, you can avoid both stockouts that delay repairs and over-ordering that clutters storage and strains budgets.

Lower Costs

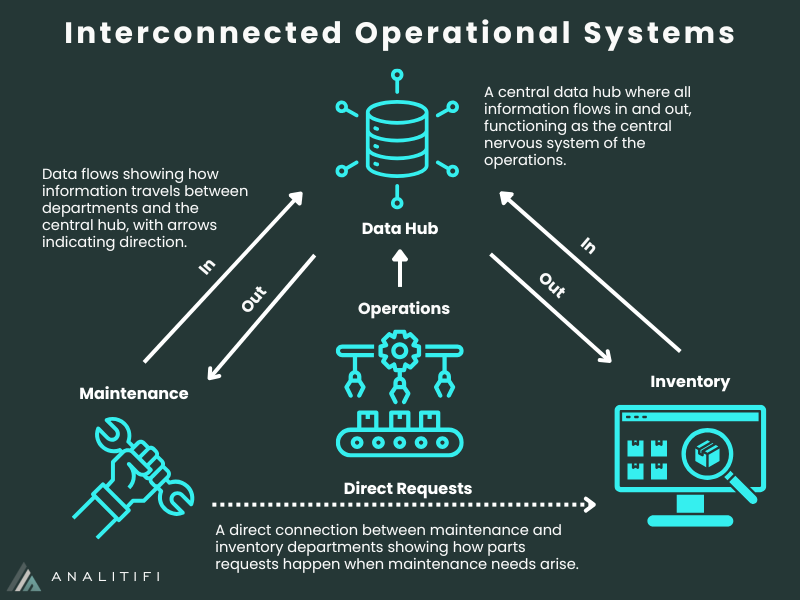

When maintenance, operations, and finance teams share visibility through unified dashboards, decisions become more strategic. Reduced downtime boosts output without expanding infrastructure. Fine-tuned maintenance extends asset life and cuts replacement expenses. Efficient operations lower energy use and optimize labor. This alignment creates a feedback loop where every department contributes to, and benefits from, data-driven improvements, ultimately leading to a leaner, more resilient operation.

When insights are shared and acted on across teams, the entire operation becomes more agile, efficient, and prepared for the future. The key extends beyond data collection to knowing how to apply it effectively. With the right tools and mindset, your facility can shift from reactive problem-solving to continuous improvement, where every decision is backed by evidence and aligned with your broader goals. By analyzing past performance, organizations can chart a clear course forward using data-driven insights.

Conclusion

Every dashboard number holds the potential to spark action and drive improvement. Behind every chart lies the potential to reduce downtime, lower costs, streamline maintenance, and increase output. Whether it’s identifying inefficiencies, uncovering hidden patterns, or aligning teams around shared goals, data is the key to transforming how your operation runs.

Manufacturers who embrace a data-driven mindset don’t wait for problems to surface, they anticipate and prevent them. This shift moves your team away from fragmented reporting and gut-based decisions toward a unified, insight-led approach that drives measurable results.

Success comes from enabling smarter operations, not merely chasing the latest technology. When maintenance teams can visualize risk in real time, when operations understand production impact moment-to-moment, and when leadership can clearly connect performance to cost, every decision becomes more strategic.

If you’re ready to harness the full potential of your operational data, Analitifi is here to help. We turn complex datasets into clear, actionable insights, so your team can make faster decisions, avoid costly surprises, and turn every challenge into an opportunity.